The purpose of all expansion plug product lines is to permanently seal holes in machined castings and machined parts of all varieties.

The classic use case is sealing core holes in machined castings.

Welch Plugs

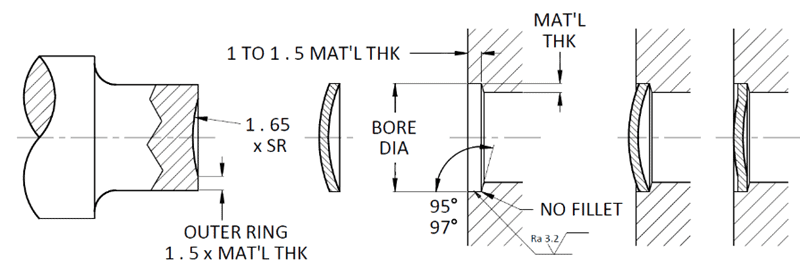

| Welch Plugs – blanked edge ENGLISH Welch Plugs – blanked edge METRIC DIN470 - SEALING – blanked edge expanded into sharp counter-bore.

- ADVANTAGE – good for limited depth and lower-pressure applications.

- PRESSURE RETENTION – up to 3 bar on 25mm diameter plugs. Blanked edge welch plugs are best used as a cover or to retain liquid at low or no pressure.

- HOLE PREPARATION – requires a machined counter-bore – more complicated than a cup plug.

- INSTALLATION – requires a close-fitting installation tool – more complicated than a cup plug.

- PRICE – blanked edge Welch plugs are less expensive than cup plugs.

|  |

| Welch Plugs – ground edge ENGLISH Welch Plugs – ground edge METRIC DIN470- SEALING – ground edge expanded into sharp counter-bore.

- ADVANTAGE – good for limited depth and higher-pressure applications.

- PRESSURE RETENTION – up to 100 bar on 1” diameter plugs. Ground edge welch plugs equal or exceed the pressure retention of cup plugs.

- HOLE PREPARATION – requires a machined counter-bore – more complicated than a cup plug.

- INSTALLATION – requires a close-fitting installation tool – more complicated than a cup plug.

- PRICE – ground edge Welch plugs are usually more expensive than cup plugs.

|  |

Cup Plugs

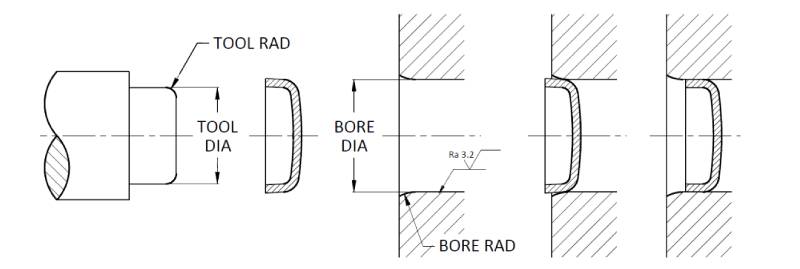

| Cup Plugs – spring lock ENGLISH Cup Plugs – METRIC DIN443 Cup Plugs – FORD WM104 + WM901 - SEALING – tapered and burnished surface compressed into finely machined through hole.

- ADVANTAGE – Simplest hole preparation and installation process plus higher-pressure performance.

- PRESSURE RETENTION – up to 60 bar on 25mm diameter plugs – well beyond a typical engine block water jacket.

- HOLE PREPARATION – straight machined through hole – easier than Welch plugs.

- INSTALLATION – shouldered installation tool with reasonable plug ID clearance – easier than Welch plugs.

- PRICE – more expensive than blanked edge Welch plugs and usually less expensive than ground edge Welch plugs. When accounting for hole preparation and installation, cup plugs are typically the most cost-effective option.

|  |

| Cup Plugs – Precision Series - SEALING – tapered and burnished surface compressed into finely machined through hole.

- ADVANTAGE – Simplest hole preparation and installation process plus higher-pressure performance.

- PRESSURE RETENTION – up to 15 bar on 6mm diameter plugs.

- HOLE PREPARATION – straight machined through hole – easier than Welch plugs.

- INSTALLATION – shouldered installation tool with reasonable plug ID clearance – easier than Welch plugs.

- PRICE – more expensive than blanked edge Welch plugs. Typically, smaller than what is offered in ground edge Welch plugs.

|  |