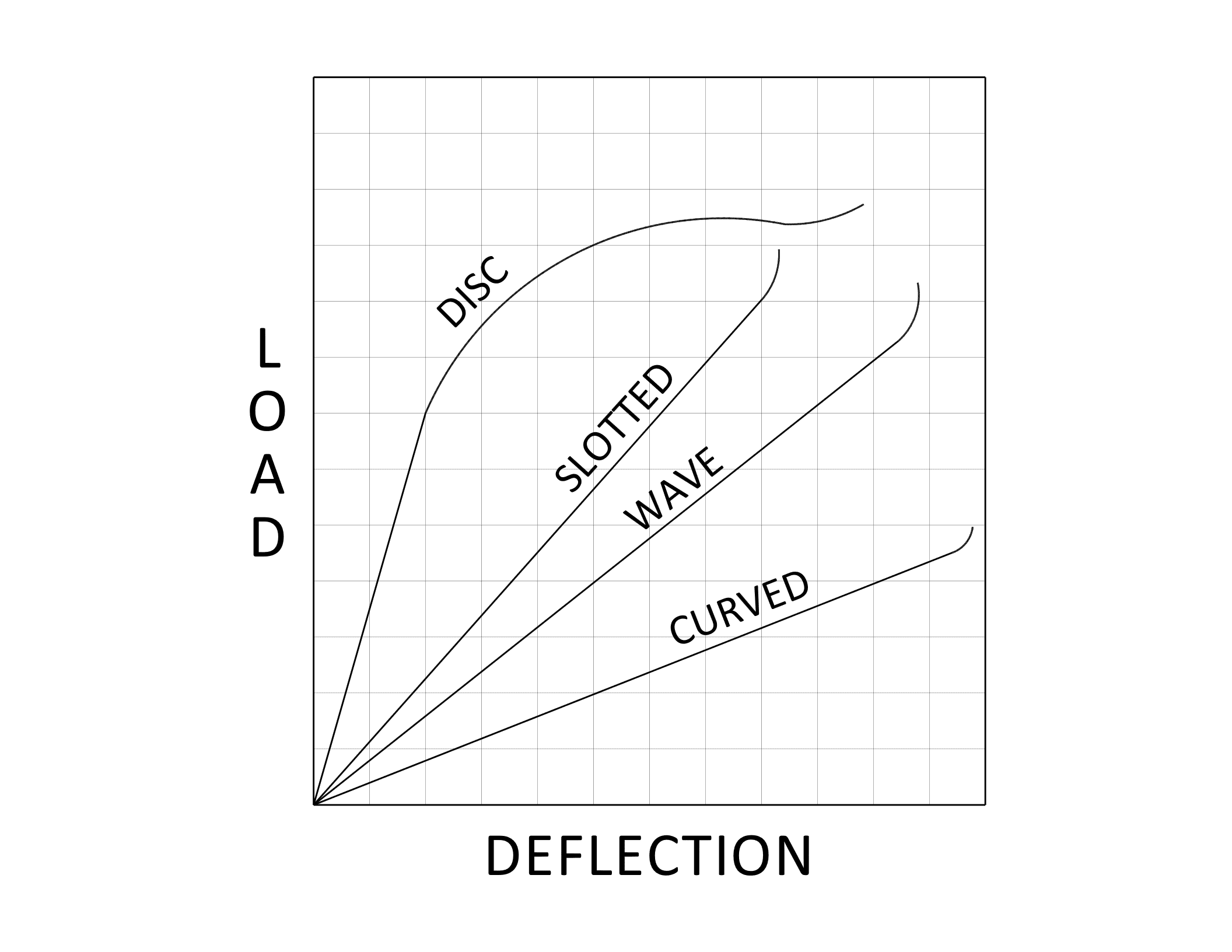

This graph illustrates general the general stress strain behavior of spring tension washer types relative to each other.

(note – this graph is not to scale)

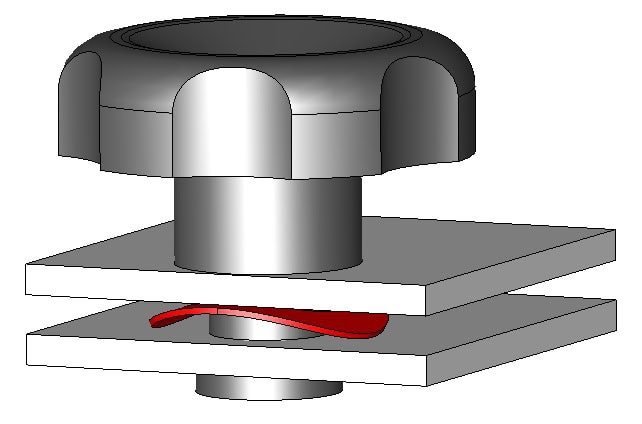

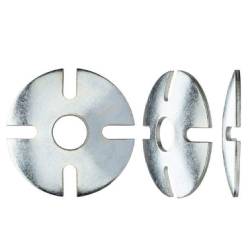

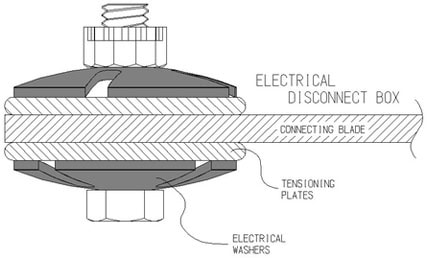

Spring tension washers have a wide range of mechanical uses in an even wider range of products.

Hubbard Spring’s general-purpose spring tension washers are the most cost-effective and for applications not requiring a controlled force at a specific height.

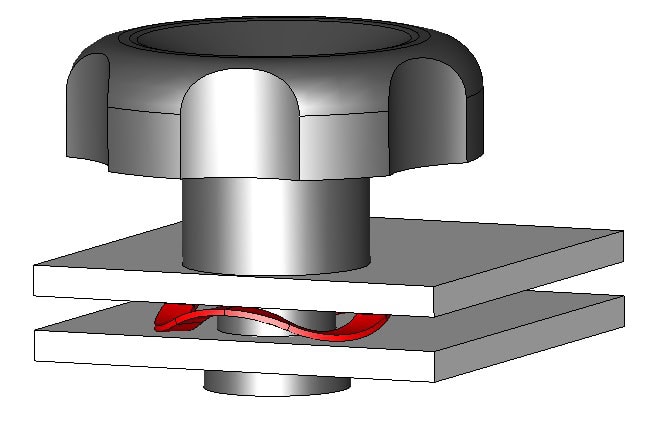

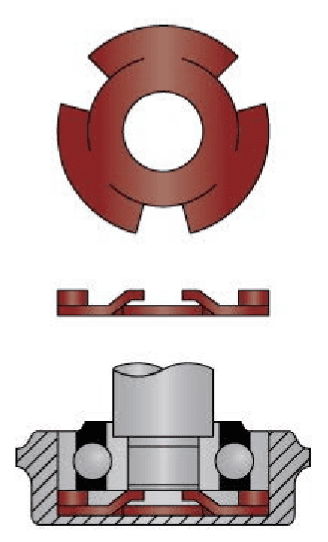

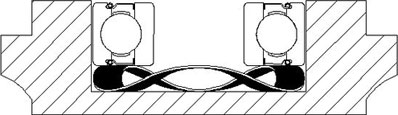

Hubbard Spring’s load rated spring tension washers were originally engineered for the side loading of bearings in housings. These spring tension washers have a controlled force at a specific height. They have more processing steps and controls than our general-purpose series.

Load rated spring tension washers are also be used in applications other than pre-loading of bearings – anywhere consistent and repeatable load in a tight space is required.